Why Draft-Proof the Room (Carefully)

Air leaking around doors, rim joists, and pipe or duct penetrations wastes energy and creates cold spots. Sealing with weather-stripping and caulk is among the most cost-effective upgrades for existing homes (see NRCan’s Keeping the Heat In air-leakage guide). But furnace rooms aren’t like other spaces: gas appliances must have adequate combustion air and safe venting. In Ontario, fuel-burning appliances are installed in accordance with CSA B149, as adopted under the Technical Standards and Safety Act and enforced by the TSSA, which includes combustion-air provisions. Only a TSSA-registered gas technician should size openings or make changes that could affect appliance operation.

What to Seal (Quick Wins You Can Do)

Only seal items that don’t affect the appliance air supply; leave code-required openings and sizing to a licensed tech.

- Door perimeter & threshold: Add weather-stripping and a sweep to tame hallway drafts; keep any code-required louvres/under-cuts intact.

- Small wall/floor penetrations: Seal around pipes and cables with appropriate fire-stop caulk/foam where allowed; don’t cover access panels or data plates.

- Rim-joist/sill leaks near the room: Foam or caulk noticeable cracks so the whole basement holds heat better.

- Visible duct leakage: Tape short, accessible seams with HVAC foil tape; leave balancing dampers reachable. (Francis can test and seal more extensively during a tune-up.)

Smoke-pencil tip: Check air movement before/after sealing. If smoke is pulled toward a draft hood or vent connector, stop and call Francis; don’t continue sealing. This ‘spillage’ indication warrants inspection per TSSA combustion-safety practices.

What Not to Block (Safety-Critical)

- Combustion/ventilation air: Don’t cover grilles, louvres, or a dedicated combustion-air duct, even if they feel drafty. Blocking them can cause unstable flames, soot, or back-drafting. Combustion air must not be taken from bedrooms or bathrooms.

- Manufacturer clearances: Keep required space around the furnace, water heater, and vent connectors; we’ll verify distances during inspection if the manual is missing.

- Return-air path: Don’t seal the only return pathway in the basement zone; altering pressure relationships can contribute to depressurization and spillage on atmospherically vented appliances.

Combustion-Air Basics in Ontario

Many furnace rooms use a ducted outdoor air supply or door/wall louvres for combustion air. Sizing is a code calculation; don’t guess. Ontario fuel-gas guidance also prohibits drawing combustion air from bedrooms or bathrooms. Ask a licensed tech to confirm the method and size for your equipment.

CO Safety and Alarms

Draft-proofing doesn’t replace proper venting. Ontario Fire Code, Division B, 2.16 requires CO alarms where a dwelling has a fuel-burning appliance, fireplace or storage garage; install adjacent to sleeping areas and on applicable storeys as needed. For health guidance on CO hazards, see Health Canada.

How Draft-Proofing Interacts with HRVs/ERVs

If your home has a heat-recovery ventilator (HRV) or energy-recovery ventilator (ERV), good air sealing actually helps the system work as intended: the ventilator, not random gaps, controls fresh-air exchange. Don’t try to “make up” combustion air through the HRV/ERV or restrict designed combustion-air grilles to “force” more through the ventilator. Keep the systems separate: ventilation for indoor air quality; combustion-air openings for safe appliance operation. After significant sealing, Francis can rebalance your HRV/ERV to keep ventilation on target. NRCan guidance treats HRVs/ERVs as ventilation systems for indoor air quality, not as a source of combustion air.

Signs of Insufficient Combustion Air (Call a Pro)

- Pilot or main flame lifts, wavers, or rolls out.

- Sooting at the burner compartment, vent hood, or nearby surfaces.

- CO alarms chirp, or you notice headache/flu-like symptoms when the equipment runs.

- The furnace room door is hard to open when the furnace or dryer is operating (due to pressure issues).

These are red flags indicating DIY sealing and warranting a same-day inspection.

Materials & Tools Checklist

- Door sweep, weather-stripping, and quality caulking (plus fire-stop sealant where required).

- Seal accessible duct seams with UL 181 metal (foil) tape or mastic; never use cloth “duct tape.”

- Smoke pencil/incense, painter’s tape, flashlight, shop vac, and PPE (gloves, glasses, mask).

- A notepad or phone to record any labels or clearances you uncover for the tech.

A Simple, Code-Safe Plan

- Find leaks: On a breezy day, smoke-test around the furnace-room door, baseboards, sill plate, and penetrations; mark trouble spots.

- Seal non-critical gaps: Weather-strip the door, add a sweep, caulk/foam small penetrations (fire-rated where required). Leave combustion-air openings and clearances alone.

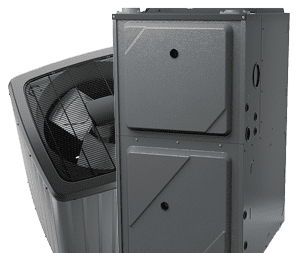

- If you have a heat pump: Keep snow/ice away from the outdoor unit’s clearance zone; don’t wrap the cabinet.

- Install/verify CO alarms: Test monthly and replace on schedule; place them where the Code requires.

- Book a professional inspection: A certified Francis technician will check draft and venting (including a spillage/back-draft test for atmospherically vented appliances), confirm combustion-air sizing, verify clearances, run a CO safety check, and tune the system for efficient, stable operation before winter.

When to Call Francis (Don’t DIY These)

- You see flame rollout, soot, or scorch marks; these can indicate spillage/back-draft or combustion problems and require same-day inspection.

- You smell exhaust, or a CO alarm activates.

- You’re unsure if a grille or door undercut is code-required.

- Bills spiked after DIY sealing, or rooms feel stuffy.

We’ll make it simple: Francis can complete draft-proofing tasks as part of Furnace Maintenance/Tune-Up and ongoing Maintenance Plans, so your home stays efficient and safe through Ottawa’s coldest nights.